Can you imagine the radical CO2 emissions rate reduction on your final product?

NOW, IT’S POSSIBLE

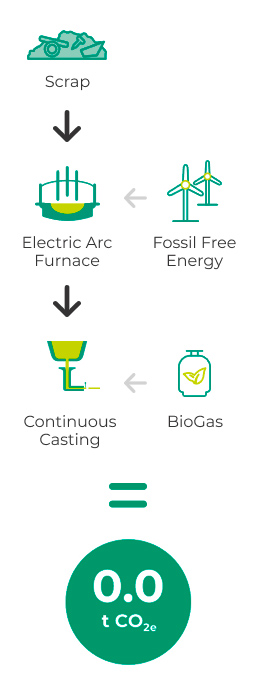

Tubos Reunidos Group has created its first Net Zero carbon Emissions Seamlees Steel Tubes and Pipes from recycled raw material to help you decrease your CO2 emissions rate.

O‑NextTM

Several decarbonization initiatives to reach Net Zero.

The emissions are not completely zero, but so small that we guarantee that it is less than 0.045 t CO2e emissions per t steel, and thus rounded to 0.0.

We will replace our current energy sources with 100% Fossil Free Energy and use of Biofuels to produce our O‑NextTM seamless steel tubes and pipes, thanks to agreements with our energy suppliers.

We already have agreements with utilities and energy suppliers.

2024 marks the beginning of a new era with our O‑NextTM range of seamless steel tubes, certified by Tecnalia to ensure the highest quality and responsability.

Looking ahead, in 2025, the EPDs (Environmental Product Declaration) of O‑NextTM will be certificated by an external official certifying company.

First O‑NextTM

productions will be certificate by Tecnalia

O‑NextTM EPD:

Available in 2025

O‑NextTM is the range of low-emission seamless steel tubes from Tubos Reunidos Group. Made with recycled raw materials and fossil-free energies. Its manufacturing process achieves an emission of 0.0 t of CO2e per tonne of manufactured steel, in scope 1 and 2.

To achieve our decarbonisation goals and respond to the growing demand for low-emission products in the market. Our position and technological production capacity, as well as our commitment to the environment, has motivated us to develop a product that makes it easier for our customers to achieve their neutrality goals. This product is available now.

Because it helps our customers drastically reduce their carbon footprint and achieve their environmental and decarbonization goals.

The quality and properties of the tube do not vary between tubes that meet the same standards and grades.

The O‑NextTM range offers products of 0.0 t CO2e emissions per tonne of pipe produced in terms of energy use and steelmaking (scope 1 and 2). Whereas, for the same range, our standard pipes emit 0.8 t per tonne of fabricated seamless steel pipes.

Currently according to our EPD S-P-11702, our emissions in scope 1,2 & 3 for a structural carbon steel grade S355J2H are 1,2 t CO2e per ton produced, while with the O‑NextTM range in scope 1,2 & 3 the emissions are only 0,4 t CO2e per ton of pipe produced.

Yes. In the first production campaign in 2024, emissions will be certified by an official external certifying company, guaranteeing the declared CO2e values of the O‑NextTM range. By 2025 we will have the corresponding EPD (Environment Product Declaration).

The range is already available, but the first production campaign will take place when it is covered by our customers' requests. Your sales contact will be able to advise you in more detail on the products you need for your business.

The main advantage of O‑NextTM is that you and your end users will be able to reduce the impact of your emissions in scope 3 of your products' life cycle assessment. The only downside is that the initial production costs are higher, which makes it more expensive to produce and therefore comes at a higher price. However, we believe that this price difference will be lower than the costs generated by the carbon emissions that will be applied to the industry.

The O‑NextTM range maintains the high quality of Tubos Reunidos Group's products. The main factor is the higher production costs due to the use of energy from renewable sources such as wind, solar, biofuels or green hydrogen, which are more expensive, in lieu of using fossil fuels.

Yes. We will continue to supply our usual range of products in line with market demand. Although we estimate that the demand for the O‑NextTM range will increase, we will continue to focus on our customers by offering them a wide range of products tailored to their needs.

We will continue to respond to all our customers as we have done so far and with the same delivery service that they value so much.

O‑NextTM is a type of seamless steel pipe with almost zero emissions in its manufacture, but not completely free of fossil fuels due to the raw materials needed to produce the steel.

If you would like more information, you can ask your sales contact at Tubos Reunidos Group or Contact us at: sales@tubosreunidosgroup.com.

Connect with O‑NextTM

Connect with our experts today

Take the first step towards innovate solutions with O‑NextTM. For information or to speak with our sales team: